Laser Seam Tracking

Seam Tracking, also known as Joint Tracking, involves real-time tracking just ahead of where the weld is being deposited. This allows for not only robot or machine trajectory shifts, but also adaptive control such as adjustments to voltage, wire feed, or travel speed to change weld bead formation.

LAS-TRAC/E™

High-speed and high-accuracy seam tracking laser-vision system for laser welding, laser hybrid welding and laser brazing. LAS-TRAC/E™ is designed to perform real-time laser seam tracking of the laser welding joint to ensure perfect positioning of the laser welding spot within the joint. LAS-TRAC/E™ system handles complex seam trajectories and critical part variability. It is suitable for any weldable base metal from carbon steel to stainless steel, as well as highly reflective aluminum alloys.

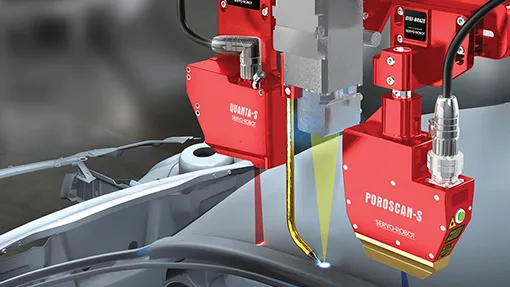

DIGI-BRAZE™

DIGI-BRAZE™ is an intelligent modular laser brazing vision system. It integrates high-precision 3D laser-cameras together with a high-quality industrially proven laser beam delivery head for up to 30kW* and the wire feeder into one compact rugged package for real-time seam tracking, weld inspection and process control in a single operation. The DIGI-BRAZE™ system precisely laser brazes linear or curved joint on articulated robots, thanks to the patented software developed by SERVO-ROBOT. Typical application: roof to body side and trunk lid in automotive industry.

*Up to 10kW for Laser-X model. Contact SERVO-ROBOT for more details.

MDL/E™

The MDL/E™ is an intelligent modular laser processing system. It integrates a dedicated high precision 3D laser vision system for tracking and weld inspection to an industrially proven laser beam delivery head together into one compact rugged package that offers the perfect solution for the adaptive control of high speed welding machines or robotic laser welding systems. This system has a new generation control unit capable of performing both tracking and inspection functions simultaneously. It includes the capability of welding curved joints and complex 3D parts with either articulated robots or a multi-axes CNC machine.

Image courtesy of S-R Korea